Semiconductor Device Types: An Engineering Guide to Core Concepts and Families

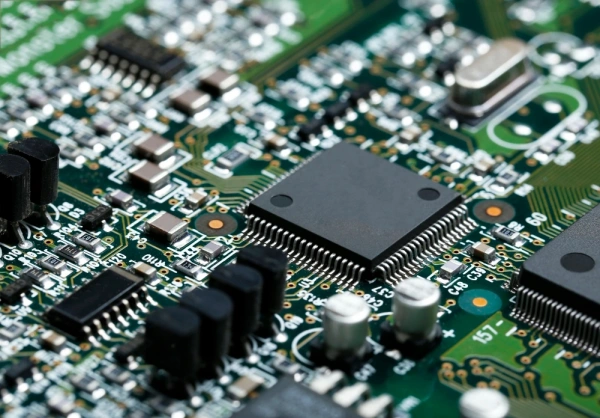

1. What Are Semiconductor Devices? (Definition and Value)

1.1 Definition and Core Function: The Foundation of Solid-State Electronics

Semiconductor devices are fundamental to modern electronics, utilizing the unique electrical properties of semiconductor materials to precisely control electric current. An authoritative definition describes a semiconductor device as an electronic component whose conductivity lies between that of a conductor (like copper) and an insulator (like glass). It functions by controlling charge carriers (electrons and holes) to achieve rectification, amplification, switching, sensing, or photoelectric conversion. These devices conduct electricity in a solid state, a key difference from vacuum tubes, which has led to significant reductions in size, power consumption, and increased reliability of electronic components.

The strength of semiconductor materials lies in the ability of engineers to manipulate their electrical behavior through sophisticated methods. The primary methods include doping, which involves the deliberate addition of impurities (such as Phosphorus or Boron) to increase the number of free electrons or holes; and applying electric fields, light, or heat to change the material’s conductivity. By precisely controlling the location and concentration of these doped regions, engineers can fabricate billions of tiny functional units, such as diodes and transistors, on a single silicon wafer, forming the basis of modern integrated circuits (ICs).

1.2 Why Important: Key Components of Modern Electronic Systems

Semiconductor devices are irreplaceable, acting as critical components driving modern society. From the Central Processing Units (CPUs) in personal smart devices to the Radio Frequency (RF) front-ends in global communication networks, from power inverters in electric vehicles to industrial automation control systems, virtually all electricity-dependent applications rely on semiconductor devices. They are essential not only for complex computation and communication but also for efficient energy conversion and management.

1.3 Core Concepts Overview: The Four Core Concepts of the Semiconductor World

Band Theory: The fundamental reason for conductivity differences lies in the material's energy band structure. Semiconductors possess a moderate Bandgap (Eg), allowing electrons to be excited into the conduction band to conduct current at room temperature, whereas insulators have energy gaps that are too large. Band theory sets the physical limits for designing devices that tolerate high voltage and high temperature.

Doping and PN Junction: Through doping processes, semiconductor material is categorized into N-type (majority carriers are free electrons) and P-type (majority carriers are holes). When N-type and P-type semiconductors are joined, a PN junction is formed. A region naturally depleted of free carriers, known as the Depletion Region, forms at the junction, creating a built-in electric field, or natural voltage barrier.

PN Junction: The Current Switch/Control Element: The PN junction is the foundation for all rectification and switching functions. Applying an external voltage (bias) controls the width and height of the depletion region, thereby determining whether current can flow. When a forward bias voltage exceeds the built-in barrier (e.g., approximately 0.7V for Silicon), the depletion region narrows sharply, and current increases exponentially.

Electric Field Control (FET) vs. Current Control (BJT): This is the key distinction between the two major classes of transistors.

- Field-Effect Transistors (FET): The most common example is the MOSFET, which is a voltage-controlled device. Applying a voltage to the Gate terminal generates an electric field that modifies the conductivity of the channel region, thereby controlling the current flow between the Source and Drain. Due to the insulating layer between the gate and the channel, MOSFETs feature extremely high input impedance, require very low drive power, and are highly suitable for high-speed switching and digital logic.

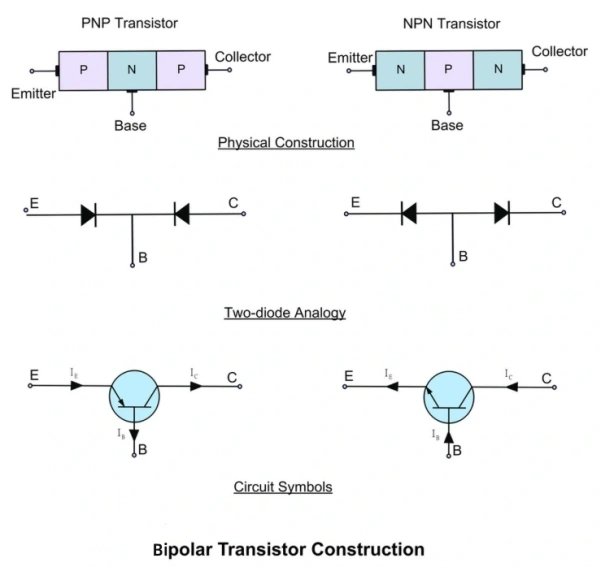

- Bipolar Junction Transistors (BJT): While the movement of carriers is physically controlled by the Base-Emitter voltage (VBE) (and collector current IC has an approximate exponential dependence on VBE), in circuit engineering, the BJT is most often modeled as a current-controlled device, where the Base current (IB) controls the Collector current (IC). BJTs involve the transport of both electrons and holes, thus earning the name "bipolar."

2. Essential Physics and Parameters (Engineering Datasheet Analysis)

2.1 Material and Bandgap: The Physical Limits of Performance

The material's bandgap (Eg) dictates the electrical and thermal limits of the device. First-generation Silicon (Si), with its mature processes and low cost, remains dominant, but its 1.12 eV bandgap constrains its performance in high-voltage, high-temperature, and high-frequency applications.

Third-generation Wide Bandgap (WBG) materials, such as Silicon Carbide (SiC, ≈ 3.3 eV) and Gallium Nitride (GaN, ≈ 3.4 eV), possess a critical electric breakdown field (Ec) several times higher than that of Si. This high Ec is essential for achieving breakthroughs in power device performance. In traditional Si devices, increasing the breakdown voltage (BV) requires thickening the semiconductor drift region, which inherently increases the on-state resistance (Rds(on)) and conduction losses. WBG materials solved this trade-off: they allow engineers to design devices with significantly higher voltage tolerance (BV) but thinner drift regions, thereby achieving remarkably low Rds(on) while maintaining high voltage ratings. This is the fundamental reason SiC/GaN achieve high efficiency in high-power applications.

2.2 PN Junction and Depletion Region: Intuitive Meaning of Biasing

Forward Bias: The external voltage is applied in the opposite direction to the internal barrier. When the external voltage reaches or exceeds the barrier voltage (approx. 0.7V for Si), the depletion region narrows sharply, allowing majority carriers to flow, and the device turns ON.

Reverse Bias: The external voltage is applied in the same direction as the internal barrier. This widens the depletion region and increases the barrier height, blocking current flow, and the device is in the OFF-state, with only a tiny reverse saturation current flowing.

2.3 Key Parameters Snapshot: Understanding Device Performance Bottlenecks

- Threshold Voltage (Vth): The minimum Gate-Source/Emitter voltage required to initiate the conductive channel in a MOSFET or IGBT.

- On-State Resistance (Rds(on)): Measures the resistance of a MOSFET when it is fully ON. It is the central metric for calculating conduction losses (Pcond = ID2 · Rds(on)).

- Breakdown Voltage (BV): The maximum voltage the device can withstand in the reverse-blocking mode.

- Switching Speed and Gate Charge (Qg): Qg is the total charge required to fully switch the device from OFF to ON (Qg = Qgs + Qgd). This parameter directly determines the complexity of the drive circuit and the time required for switching. A lower Qg results in faster switching speeds and lower switching losses (Psw).

- Power Dissipation and Thermal Resistance (Rth): Thermal resistance measures the efficiency with which the device dissipates heat from the internal junction (j) or channel (ch) to the external environment. Rth(j-c) or Rth(ch-c) (junction/channel-to-case thermal resistance) is a critical parameter.

2.4 Basic I–V Relationships (Non-Derivation): Diode and Transistor Operating Regions

Diode I–V Exponential Law: The current-voltage relationship of an ideal diode is exponential: I = I0 (e^(qV/nkT) − 1). This exponential dependency makes the device highly sensitive to temperature variations.

MOSFET I–V Region Concepts:

- Linear/Ohmic Region: When VDS is low, the device acts as a resistor, and the drain current (ID) increases linearly with VDS. This is the operating region for power MOSFETs when acting as an ON-state switch.

- Saturation Region: When VDS is high and the channel is pinched off, ID is primarily controlled by VGS and changes minimally with VDS. This is the operating region when the MOSFET functions as an amplifier or current source. It is important to note that unlike the “saturation” region in BJTs, a power MOSFET should ideally operate in the Linear/Ohmic region when used as a switch.

3. Overview of Common Device Types

The semiconductor device family is vast, with core differences in structure, carrier type, and control mechanism.

| Device Type | Control Method | Typical Function/Application | Key Characteristic/Advantage |

|---|---|---|---|

| Diode | PN Junction/Light/Bias (Uncontrolled) | Rectification, Voltage Reference, Photoelectric Conversion | Unidirectional conductivity, Schottky near-zero trr |

| Bipolar Junction Transistor (BJT) | Current Control (IB) | Analog Small-Signal Linear Amplification | High transconductance, excellent linearity |

| Field-Effect Transistor (FET) | Voltage Control (VGS) | High-Speed Switching, Digital Logic, Current Amplification | Extremely high input impedance (Zin), unipolar operation |

| Power Switch (IGBT/MOSFET) | Voltage Control (VGS) | High Power, High Voltage/High Frequency Switching | Low Conduction Loss (Rds(on)) or Low Switching Loss (Qg) |

| Thyristor | Gate Pulse Trigger (Latching) | High-Power AC Control, Rectification | Unique latching characteristic, high current capacity |

| RF/Microwave Device (HEMT) | Voltage Control (VGS) | Millimeter-Wave Amplification, High-Frequency Power | Extremely high electron mobility (2DEG), extremely high operating frequency |

| Sensing and MEMS | Environmental Physics (Light, Heat, Pressure, Gas) | Conversion of Physical/Chemical quantities to Electrical Signals | Based on conductivity changes, IC compatible |

3.1 Diodes

Rectifier Diode: The classic PN junction structure, primarily used to convert alternating current (AC) to direct current (DC) in line-frequency or mid-frequency circuits, often featuring high breakdown voltages (typically 200V to 1000V).

Schottky: Formed by a metal-to-N-type semiconductor contact, operating as a unipolar device. Its core advantage is a very low forward voltage drop (VF). The Schottky diode generates virtually no minority carrier reverse recovery (trr is negligible), though it is not strictly zero and is still affected by junction capacitance. This characteristic significantly reduces high-frequency recovery losses, making it the preferred choice for secondary rectification in low-voltage, high-frequency switching power supplies.

Zener: Uses a heavily doped PN junction, specifically designed to operate stably in the reverse breakdown region. Commonly used as a voltage reference or in voltage clamping protection circuits, leveraging its stable reverse breakdown voltage characteristic.

Photodiode / Solar Cell: Utilizes the photovoltaic effect in semiconductor materials, absorbing photons to generate electron-hole pairs, converting light energy into electrical energy.

LED / Laser Diode: Current injection across a forward-biased PN junction causes carriers to recombine, emitting light (electric-to-light conversion). LEDs primarily rely on spontaneous emission and cover a power range from milliwatt to multi-watt for lighting and displays. Laser diodes rely on stimulated emission, producing coherent, high-power-density light beams. Widely used in optical communication, measurement, and storage (e.g., CD/DVD).

3.2 Bipolar Junction Transistors (BJT)

BJT is a current-controlled device, involving the transport of two types of carriers (electrons and holes), hence bipolar.

Features: BJTs use an NPN or PNP three-layer structure and feature high transconductance. When operating in the Active Region, they can provide highly linear current amplification.

Application: Primarily used for small-signal amplification, current mirrors, and precise linear signal processing in the analog circuit front-end. Engineers establish a stable quiescent operating point (Q-point) to ensure low-distortion signal amplification.

3.3 Field-Effect Transistors (FET)

FETs are voltage-controlled devices, relying solely on majority carriers for conduction (unipolar), and feature high input impedance.

MOSFET (Core): Features an insulated gate structure (Metal-Oxide-Semiconductor), with extremely high input impedance (up to 1014 Ω). Due to superior switching characteristics and ease of large-scale integration, MOSFETs are the dominant device in digital logic and power electronics.

JFET: The gate is formed by a PN junction, resulting in high input impedance (typically 109 Ω, lower than MOSFETs). JFETs excel in low-noise amplification and specific analog applications requiring superior linearity.

3.4 Power Devices

Power MOSFET (Si): Silicon MOSFET solutions are mature across low voltage to medium-to-high voltage (including 600V–900V Super Junction) applications. Above 400V, device selection is typically a trade-off between SJ MOSFET / IGBT / SiC based on switching frequency and loss targets. Si MOSFETs excel at high-frequency switching (>100 kHz) due to their low Rds(on) advantage.

IGBT (Insulated Gate Bipolar Transistor): Suitable for medium-to-high voltage (typically >400V) and high-current industrial applications, such as motor drives. The IGBT combines the voltage control of the MOSFET with the high current density of the BJT. Its drawback is the Tail Current during turn-off, caused by the slow recombination of minority carriers, which severely limits its switching frequency (usually below 20 kHz).

Wide Bandgap Devices (SiC / GaN):

- SiC MOSFET: Possesses extremely high voltage tolerance, used in 600V to 10kV applications. It is ideal for high-voltage, high-power conversion (e.g., EV traction inverters). In practical design, SiC MOSFETs are often paired with external SiC Schottky diodes to reduce reverse recovery loss and noise, as the intrinsic body diode performance is typically suboptimal.

- GaN HEMT: Primarily used in the medium-to-low voltage range (30V to 650V). Its core advantage is extremely low total Gate Charge (Qg), enabling extremely high switching frequencies in the MHz range. GaN is suitable for applications demanding extreme miniaturization and high power density, such as consumer fast chargers and data center power supplies. However, achieving MHz switching requires managing constraints related to gate loop parasitics, drive stability, and EMI; system-level magnetics and layout ultimately determine the achievable frequency.

3.5 Thyristors and Family (Thyristors / SCR / Triac)

Features: The Thyristor (SCR, Silicon Controlled Rectifier) is a PNPN four-layer structure device. Its unique feature is the latching characteristic: once triggered into conduction by a gate pulse, the device remains ON even if the gate signal is removed, provided the anode current does not drop below its Holding Current.

Application: Primarily used for high-power rectification, AC power control (such as soft-start, dimming), and industrial power supplies. The TRIAC (TRIode for Alternating Current) is a variant of the SCR capable of controlling both half-cycles of AC current.

3.6 RF & Microwave Devices (RF & Microwave)

HEMT / pHEMT, GaAs/GaN Devices: High Electron Mobility Transistors (HEMTs) form a Two-Dimensional Electron Gas (2DEG) at the junction interface between materials with different bandgaps (heterojunction, such as AlGaN/GaN), providing extremely high electron mobility.

Application: HEMTs can operate at millimeter-wave frequencies and are used in high-frequency front-ends, base stations, radar, and satellite receivers. GaN HEMTs offer superior performance over traditional GaAs devices in microwave wireless communication (e.g., 5G power amplifiers) due to their higher critical electric field and power density.

3.7 Sensing and MEMS Related

Fundamental Principle: Semiconductor sensors utilize the sensitivity of semiconductor materials to environmental stimuli (e.g., temperature, pressure, gas concentration, light) to convert physical or chemical quantities into measurable electrical signals. Their operation is based on changes in electrical conductivity or resistance.

Types and Basis:

- Gas Sensors: Utilize chemical reactions that alter the surface charge of the material, thereby changing its conductivity.

- Temperature Sensors: Based on the thermistor effect, utilizing the temperature-dependent resistance characteristics of semiconductors.

- Pressure Sensors: Utilize the piezoresistive effect or capacitive effect of silicon to convert mechanical deformation into electrical signals.

4. Engineering Design Partner: FDPCB One-Stop Manufacturing and Core Advantages

4.1 One-Stop PCBA Manufacturing and Supply Chain Integration

After the selection and circuit design of semiconductor devices are finalized, the critical step of translating the design into a reliable product lies in supply chain management and manufacturing. FDPCB provides a Turnkey PCB Assembly service, assisting engineers with a smooth transition from prototype design to mass production.

Customers only need to provide Gerber files and the Bill of Materials (BOM) list to execute the entire process of PCB fabrication, component procurement, and precision assembly. This model significantly simplifies project management, offering the advantage of a single supplier interface.

Upload & Get BOM Service at FDPCB

Core Manufacturing and Assembly Capabilities:

- PCB Fabrication: Supports the manufacturing of complex structures, including up to 32 layers, High-Density Interconnect (HDI), Flexible (Flex), and Rigid-Flex boards. Manufacturing capability ensures high precision, with minimum line width/spacing down to 3 mils. Production scale is flexible, covering quick-turn prototypes to large-scale mass production.

- Precision Assembly: Services include SMT/THT mixed assembly and BGA assembly, with high-precision capability to handle 01005 micro-components and 0.25mm pitch BGAs. Assembly processes adhere to strict IPC-A-610 Class 2 & 3 quality standards, utilizing advanced inspection tools like X-ray, AOI (Automated Optical Inspection), and supporting free functional testing.

- Supply Chain and Efficiency: Features over 600K types of local component inventory, supporting Zero Minimum Order Quantity (Zero MOQ) and direct manufacturer pricing. Project initiation is rapid (launch within 24 hours, 5-day standard turnaround), with free DFM/DFA (Design for Manufacturing/Assembly) analysis provided to effectively prevent manufacturing errors.

5. Glossary

| English/Abbreviation | Definition |

|---|---|

| Bandgap | The energy difference between the conduction band and the valence band, determining the semiconductor material's intrinsic electrical properties and temperature tolerance |

| Doping | The process of intentionally introducing impurity atoms into a semiconductor crystal to precisely control its majority carrier type and concentration |

| PN Junction | The interface connecting P-type and N-type semiconductors, forming the fundamental structure of diodes and transistors |

| Breakdown Voltage (BV) | The maximum voltage the device can withstand in the reverse-blocking mode, a crucial limit for reliability design |

| Rds(on) | The equivalent resistance between the Drain and Source when the MOSFET is fully conducting, used to calculate conduction loss |

| Gate Charge (Qg) | The total electrical charge required to turn a field-effect device (MOSFET/IGBT) ON or OFF, a key parameter determining switching speed and drive power |

| Reverse Recovery (trr) | The time required for minority carriers to be cleared when a bipolar device (like a PN diode or IGBT body diode) switches from conducting to blocking, a major source of high-frequency loss |

| SOA (Safe Operating Area) | The region defined by voltage and current combinations where the device can safely operate under specified conditions and temperature |

6. Frequently Asked Questions - Engineer Q&A

How to quickly distinguish between MOSFET and IGBT?

Distinction Dimension: IGBTs are better suited for handling high voltage (>400V) and large currents, with low conduction loss, but their switching frequency is generally limited to below 20kHz due to minority carrier effects. MOSFETs excel at low voltage (<250V) and high frequency (>100kHz), with extremely fast switching speed. For high-frequency applications above 600V, SiC MOSFETs should be considered.

What is the intuitive difference between SiC and GaN?

Distinction Dimension: SiC is stronger in voltage and current handling capability (>600V, high current), making it the preferred choice for high-voltage, high-current industrial and automotive applications. GaN offers advantages in extremely high frequency (MHz range) and ultimate power density, suitable for medium-to-low voltage high-frequency switching, such as consumer fast chargers and high-frequency DC/DC converters.

Why is the Schottky diode more "power-saving"?

The Schottky diode is a unipolar device that does not rely on minority carriers for conduction. Consequently, it has a very low forward voltage drop (VF), significantly reducing conduction loss. Crucially, it has no reverse recovery time (trr), eliminating recovery loss during high-frequency switching and thus achieving higher efficiency.

7. Conclusion and Outlook

Semiconductor devices are the backbone of electronics, with their performance dictated by material science, precise physical structure, and stringent manufacturing processes. When selecting a device, engineers must cross-match the "three essential elements" (voltage, current, and frequency) with the four key parameters (BV, Rds(on), Qg, Rth).

The power electronics sector is currently undergoing a major transformation driven by SiC and GaN. Wide bandgap materials have overcome the inherent trade-off between conduction loss and switching loss found in traditional Si devices for high-voltage and high-frequency applications. This enables system designs to achieve higher efficiency and unprecedented power density. In the future, as the manufacturing costs of WBG devices decrease and the supply chain matures, they are expected to take central roles in high-growth areas such as electric vehicles, data centers, and renewable energy, pushing the entire electronic system toward smaller, faster, and more efficient development trends.

PCB Prototype

PCB Prototype Flex FPC

Flex FPC Rigid-flex PCB

Rigid-flex PCB Aluminium PCB

Aluminium PCB.png) 3D Printing

3D Printing News

News PCB Technology

PCB Technology Electronic components

Electronic components About Us

About Us Contact Us

Contact Us PCB Capability

PCB Capability SMT Capability

SMT Capability Procurement

Procurement Payment Methods

Payment Methods Shipping Methods

Shipping Methods

_复制.png)